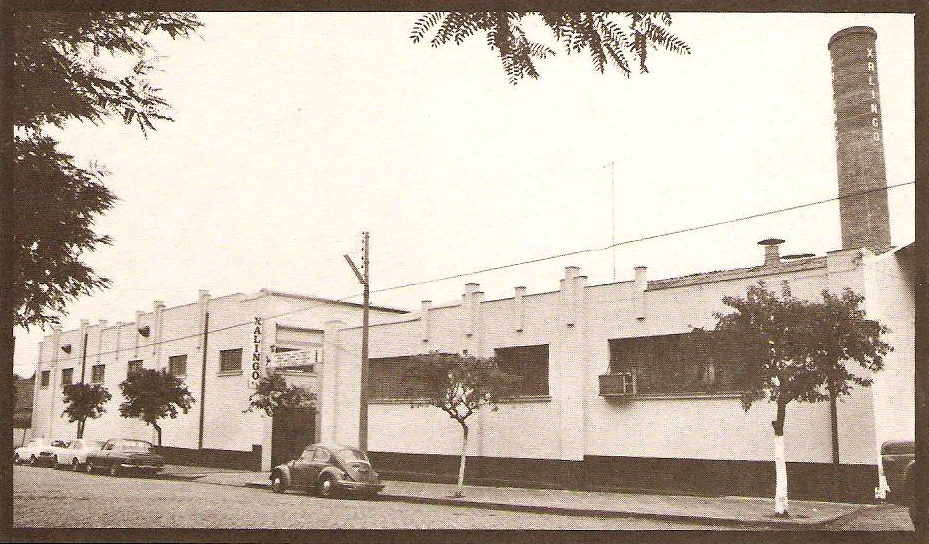

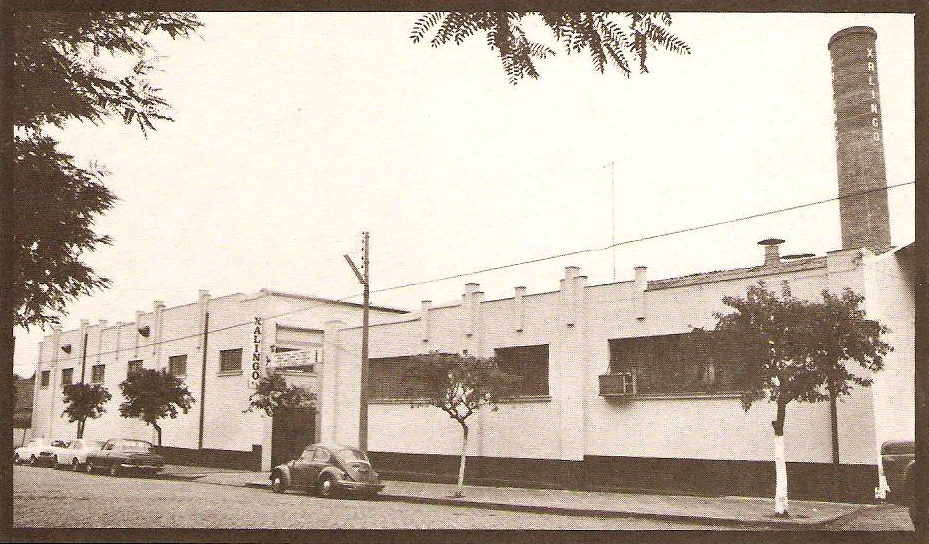

Xavier Brauger & Cia. Ltda., fundada em 30/09/1947, iniciou suas atividades com manufatura de madeira, fabricando brinquedos, material escolar e utilidades domésticas.

Somos a Xalingo S/A Industria e Comércio, uma empresa com 75 anos de história. Estamos aqui para estimular o lazer e a educação, desenvolvendo produtos e brinquedos que auxiliam no desenvolvimento social e intelectual das crianças.

Na nossa loja você encontra muitos produtos que fizeram e fazem parte da infância dos pequenos!

Eles são fofos! São amigos! São divertidos! São os FOFOSSAUROS!

Conheça um pouco mais de cada um deles!

A Xalingo Soluções agora é AgriplaX, uma unidade de negócios do Grupo Xalingo voltada para a solução de produtos em plástico para o Agronegócio. Já são 25 anos de história neste segmento, mas agora com uma marca renovada para interagir mais fortemente com nossos clientes em todo Brasil.

Jogos, curiosidades, piadas e muito mais para o público infantil!

A Miper Multimatrizes agora é InomaX uma unidade de negócios do Grupo Xalingo especializada desde o projeto até a fabricação de moldes, estampos e prestação de serviço de usinagem, com clientes espalhados por todo o Brasil.

Um espaço para pais, tutores e professores, com material e sessões específicas para cada área.

Xavier Brauger & Cia. Ltda., fundada em 30/09/1947, iniciou suas atividades com manufatura de madeira, fabricando brinquedos, material escolar e utilidades domésticas.

Início da produção de brinquedos e material escolar produzidos em plástico, com a compra da primeira injetora.

Ampliamos ainda mais a atuação em brinquedos com a incorporação de itens soprados.

Diversificando sua capacidade de transformação plástica com a aquisição da primeira máquina de rotomoldagem, que permite a entrada no segmento de peças plásticas "grandes".

Diversificando a atuação, criando nova oportunidade de negócios: Xalingo Soluções Industriais, voltada para a produção de peças plásticas para a industria em geral, principalmente para o agronegócio.

Aumentamos nosso parque fabril em mais de 20.000m2, agora com um total de 36.000m2 no total em Santa Cruz do Sul.

A Xalingo rompe fronteiras, instalando uma operação logística em Barra Velha (SC), para operar sua linha crescente de produtos importados voltada para o mercado de brinquedos, iniciando com espaço de 1.000m2 .

Inauguração do E-commerce (loja online) da Xalingo Brinquedos, seguindo a tendência do mercado de comprar pela internet.

Segue sua expansão pelo território nacional com a instalação de um parque fabril de transformação plástica em rotomoldagem, injeção e sopro, com espaço de 5.000m2.

Forma-se o Grupo Xalingo; composto por três unidades de negócio: Xalingo Brinquedos, Inomax e Agriplax. Com marcas e identidade visual renovada, o ano de 2022 é marcado pela evolução!

Em 1997 diversificou sua capacidade de transformação plástica com aquisição da primeira máquina de rotomoldagem, que permitiu sua entrada em segmento de peças plásticas “grandes” como os playgrounds; hoje a Xalingo possui mais de 50 máquinas de transformação de plástico, entre sopro, injeção e rotomoldagem – com grande capacidade produtiva.

Em 1998, a Xalingo diversificou sua atuação, criando nova unidade de negócio: Xalingo Soluções Industriais – hoje chamada de Agriplax – voltada à produção de peças plásticas para industrias em geral, em especial ao agronegócio, atendendo clientes como Stara e Vence Tudo.

Para completar, possuí uma matrizaria própria com produção de moldes para uso próprio e também para terceiros – sua 3ª unidade de negócios. A Xalingo está localizada em Santa Cruz do Sul, interior do Rio Grande do Sul, com uma indústria de 36.000m². Além disso, possuí um parque fabril em Itupeva/SP de 5.000 m², com transformação plástica em rotomoldagem, injeção e sopro, posicionado estrategicamente para facilitação logística. Esta planta conta com um show-room completo aberto à visitação. Desde 2020, possuí um centro de distribuição em Barra Velha/SC para operar sua linha crescente de produtos importados voltada ao mercado de brinquedos, iniciando com espaço de 1.000 m² que se amplia no período sazonal;

Fornecer produtos que estimulem o lazer e a educação, sem desconsiderar as oportunidades que o mercado oferece, aliando as exigências do ambiente com a utilização de tecnologias e gestão que deem a empresa a capacidade da perpetuidade.

Estar entre as três maiores fabricantes do Brasil nos negócios onde atua e com presença na América Latina até 2025.

Respeito às pessoas;

Inovação e criatividade;

Pertencimento e proatividade;

Ética e transparência;

Resultados sustentáveis.

Faça certo na primeira vez, atendendo aos requisitos aplicáveis, buscando melhoria contínua dos processos, qualidade e segurança nos produtos.

Queremos ouvir sua opinião, caso precise, entre em contato:

XALINGO S/A INDÚSTRIA E COMÉRCIO | BR 471, Km 147 | CEP 96835-642 | Santa Cruz do Sul – RS | Brasil

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |